LEADING BOLD CHANGE CONTINUES

COTY

Leading Bold Change Continues

AN INNOVATIVE APPROACH TO RESTRUCTURING

Maintaining an agile, adaptable culture for change, more than five years on

THE CHALLENGE

Coty, a global beauty company that manufactures cosmetics, skincare, fragrances, and hair color and styling products, has grown through an aggressive and fast-paced acquisition approach in recent years. In 2016, Coty acquired Proctor & Gamble’s beauty business for $12B. During this time, Coty realized their technology was no longer valid in the current business environment, and geographical demands were changing. All of this combined left Coty with an uncompetitive footprint in manufacturing. To address these challenges, the decision was made to close 5 plants (out of 18), across 4 countries (United States, Germany, Ireland, and United Kingdom), resulting in approximately 2,000 job losses.

THE APPROACH

Traditional restructurings or plant closures are typically driven from the top down, with little transparency and little involvement from employees whose jobs (and lives) will be most impacted. Coty leaders – having worked with Kotter to transform their Supply Chain from 2011 to 2014 – sought to approach this effort in a very different way. The UK plant, in Seaton Delaval, serves to illustrate a new way of thinking about restructuring.

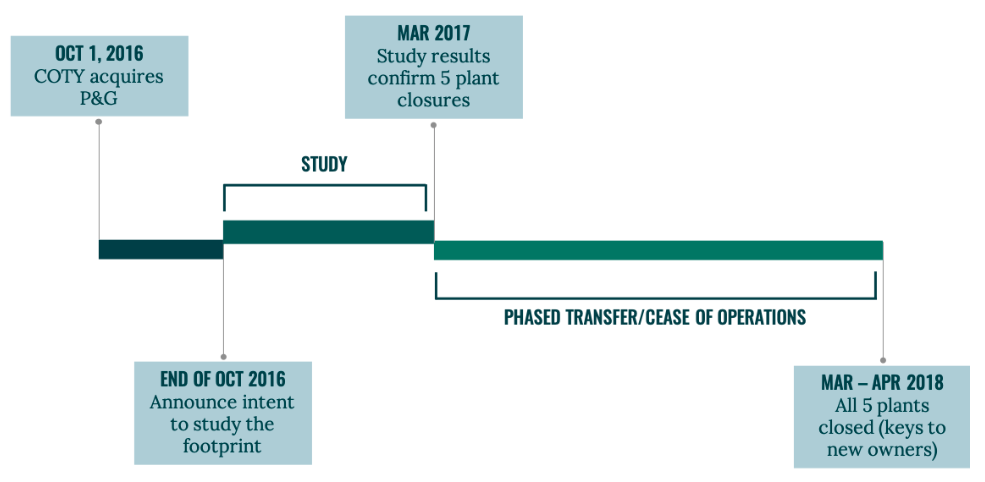

THE TIMELINE

PREPARING LEADERSHIP

While this effort could not be driven purely from the top down, the Global Manufacturing and Engineering lead knew it was critical to get buy-in from Executive Leadership and the plant manager from the outset.

Executive Leadership

The very first step was to engage Coty C-Suite leaders, with a particular emphasis on those outside of Supply Chain who had not experienced Kotter’s approach to change. These leaders had a variety of experiences with restructuring and plant closures in the past (many of which were negative), and were nervous about employees striking, leaving early or disrupting productivity if they were informed of decisions too early. Multiple working sessions were conducted to share the approach and share success stories of where the approach worked elsewhere. To maintain trust and transparency, there were bi-weekly updates to keep the entire Executive Committee informed and provide opportunities for them to challenge and ask questions.

Plant Managers

Recognizing that employees would all be looking to the plant manager for guidance, it was critical to get her on board right from the beginning. She was given time to share where she was – both emotionally and logically – and decide if she felt equipped to lead through this journey. Each leader, and employee, was given the choice whether or not to stay through the plant closure date. While this opened up the risk of losing key employees early on, it also mitigated the risk against indelible negativity spreading from those who were not invested in the process. The Seaton Delaval plant manager quickly made the decision to stay (of note, this wasn’t the case for all of the other plants, and leaders did have to replace some of those plant managers) and worked to involve herself with employees to drive the success of this effort.

ADVOCACY + SUPPORT

Throughout the process, Coty leaders invested both time and resources in supporting employees through the journey. Senior leaders regularly met with employees, empowered them to make decisions, and provided critical transition services (such as job fairs, CV support, etc.). For example, recognizing high unemployment rates in the region, and challenges due to Brexit, employees were not only given the opportunity to take a job at another Coty plant (though, very few chose to take this option), they were also provided coaching on how to “sell” themselves to future employers.

INITIAL COMMUNICATION STRATEGY

There were three key objectives as part of the overall communication strategy:

- 1.All plants performing equal or better than pre-announcement.

- 2.Employees achieve successful outcomes post-closure.

- 3.Internal and external stakeholders have their most important needs met.

Addressing the "Head"

Even before the formal announcement was made, senior leaders began sharing benchmarking data with the plant, to highlight the plant’s complacency in keeping up with market needs. This prepared the ground for the formal announcement, which was made to all 400 employees at the plant. It was focused purely on the facts – emphasizing why the decision was made, what was coming next, a concrete timetable for mapping out the closure (including a “no earlier than” date, so people knew they had a certain runway for figuring out their next step) and key milestones along this timeline. Leaders also acknowledge the questions they didn’t yet have answers to, such as the specific criteria for when/how to transition technology to other sites.

Addressing the "Heart"

The week following the formal announcement, leaders conducted eight separate working sessions with smaller groups of employees. These two-hour (or more) sessions provided employees with the opportunity to share their emotion and anger with senior leaders. The sessions varied in terms of intensity, but some were quite challenging – even aggressive. Employees voiced their fear, their disappointment in P&G for letting them down, their frustration in not being given a chance to turn things around, and their lack of trust in Coty to look after them throughout the process. These sessions were also a chance for employees to ask clarifying questions about the process, and what it meant for them – easing some of the uncertainty they felt stemming from the initial announcement.

INVOLVING THE MANY

One of the critical differentiators of Coty’s approach was the involvement of employees at all levels. The “Works Committee” – a team of about 20 people (a mixture of technicians, middle managers, and senior leaders) was formed. More than 50 volunteers raised their hands to work on this team. The final 20 were elected by their peers, with more than 90% of the plant taking part in the voting process. Once formed, this team met regularly together and with senior leaders, and took charge of leading the transition process in a variety of critical ways:

- Defining success for the plant, putting people at the center, as articulated in their team-authored Change Vision (see below)

- Engaging employees across the site, building trust and commitment throughout the journey

- Articulating key KPIs they wanted to strive to achieve, such as customer service metrics and line efficiencies

- Establishing the criteria and principles for transitioning technology to new sites

- Creating a point system to determine when people would leave the plant, recognizing there needed to be a gradual transition to new sites. This point system took into account:

- Technical skills, and what was needed based on the overall transition plan

- Years of service

- Performance

- Absenteeism

- Personal preference

- Building the compensation plan, based on the budget provided by senior leaders

- Interviewing and choosing the outplacement partner (the UK plant chose a different partner than the other 4)

- Celebrating wins broadly across the site – tied to both KPIs and personal wins, such as people leaving because they found a new job

MEASURING SUCCESS

Individual Success

Traditionally, organizations don’t measure the individual success of employees that will be laid off as part of a restructuring effort. However, Coty put individual outcomes at the center of their success criteria. They worked with each employee to define what their “invented future” would be, if they were able to turn this challenge into an opportunity. Each individual set his or her own success target – a shift in career, training in new skills, no loss of income or time between jobs, early retirement, or traveling the world. At the end of the journey, every employee was asked to honestly answer two simple questions:

- 1.Given the decision to close the plant, were you treated rightly and fairly?

- 2.Were you able, with our support, to define your own personal successful outcome, and are you on track to achieve it?

Organizational Success

In addition to individual outcomes, there were critical business targets that needed to be hit as well, including:

- Maintaining (or exceeding) productivity and safety standards (the impact of disruption risked costings Coty $1.4M in revenue per day on Seaton Delaval SKUs), such as:

- Schedule adherence

- Defect rates

- Accident rates

- Production volume

- Successful transition of technology to new sites

- Delivering closure on time and on budget

OUTCOMES

Through this approach, Seaton Delaval was able to achieve incredible individual and organizational results:

- 96% of employees answered “yes” to both questions regarding individual success outcomes

- Operational KPIs were above target until the last day

- Schedule adherence was better during the last month of operation than pre-announcement

- Plant closed on time and on budget

- Transition Services Agreement was delivered on time and in full

- Service, Quality and Safety KPIs were above target

- Recordable accident rate was less than 0.24 throughout the transition (which is half the Coty average)

- Product defect rates were at less than 800 parts per million (the best across Coty)

- Seaton Delaval was the inaugural winner of Coty’s Manufacturing Excellence Award